Stock – Stock subtab will display all aspects of stock level; stock level > 0, quarantine levels, stock levels = 0 and rejected

Active – The Active total is the sum of all the records (if any) listed under the stock tab

Quarantine – The Quarantine total is the sum of all the records (if any) listed under the quarantine tab

![]() Using the calculator button it is possible to manually check the stock totals are correct

Using the calculator button it is possible to manually check the stock totals are correct

Replenish – Records the replenishment stock level; this is for reference only as there are currently no automatic processes using this field. Used only for reporting.

Minimum – Records the minimum stock level; this is for reference only as there are currently no automatic processes using this field. Used only for reporting.

Maximum – Records the maximum stock level; this is for reference only as there are currently no automatic processes using this field. Used only for reporting.

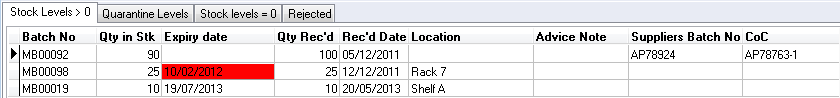

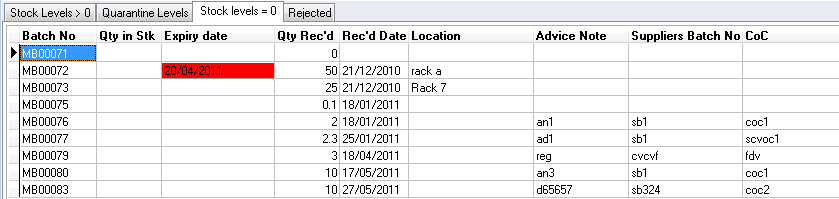

Stock levels > 0 – This holds material actually in stock, material held under this tab is in stock and available for use, only material under this tab is included in the stock active total

Batch No – Internal batch number assigned

Qty in Stk – Quantity currently in stock against the batch

Expiry date – Displays an assigned expiry date, if this expiry date has been exceeded this will highlight the field in red

Qty Rec’d – The initial quantity received

Rec’d Date – Date the initial quantity was received

Location – The assigned location of the stock

Advice Note – Advice Note provided by the supplier

Suppliers Batch No – Suppliers own Batch No

CoC – Certificate of Conformity provided by the supplier

Supplier – Supplier details for the stock batch

Consolidated – Used when consolidating materials with no traceability requirement

Source – The source of the stock entry

Unit Cost – Unit cost of the material

Cost Qty – Cost of the per quantity

Qty Rejected – Quantity of rejected materials against the batch

Source Ref – The reference of the source i.e. Purchase Order Number

Notes – Any notes applied when the batch was created

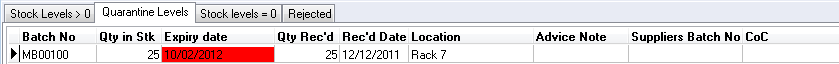

Quarantine Levels – Materials under this tab are included in the quarantine total

Batch No – Internal batch number assigned

Qty in Stk – Quantity currently in quarantine against the batch

Expiry date – Displays an assigned expiry date, if this expiry date has been exceeded this will highlight the field in red

Qty Rec’d – The initial quantity received

Rec’d Date – Date the initial quantity was received

Location – The assigned location of the quarantined stock

Advice Note – Advice Note provided by the supplier

Suppliers Batch No – Suppliers own Batch No

Supplier – Supplier of the materials

Consolidated – Used when consolidating materials with no traceability requirement

Source – The source of the quarantined stock entry

Unit Cost – Unit cost of the material

Cost Qty – Cost of the per quantity

Qty Rejected – Quantity of rejected materials against the batch

Source Ref – The reference of the source i.e. Purchase Order Number

Notes – Any notes applied when the batch was created

NumFileAttachments – Number of Document links against this batch

NumBrokenLinks – Number of Document link broken links against this batch

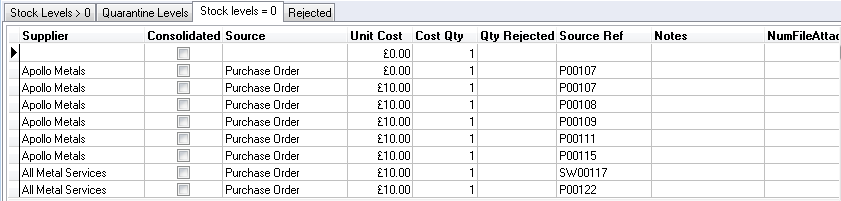

Stock Level = 0 – Displays old stock records where all the material has been used. It is possible to edit these records to put material back into stock by adjusting the quantity in stock as required. These records would then move under the stock levels > 0 tab

Batch No – Internal batch number assigned

Qty in Stk – As these stock items have been used this field should be blank

Expiry date – Displays an assigned expiry date, if this expiry date has been exceeded this will highlight the field in red

Qty Rec’d – The initial quantity received

Rec’d Date – Date the initial quantity was received

Location – The assigned location of the stock

Advice Note – Advice Note provided by the supplier

Suppliers Batch No – Suppliers own Batch No

Supplier – Supplier of the materials

Consolidated – Used when consolidating materials with no traceability requirement

Source – The source of the stock entry

Unit Cost – Unit cost of the material

Cost Qty – Cost of the per quantity

Qty Rejected – Quantity of rejected materials against the batch

Source Ref – The reference of the source i.e. Purchase Order Number

Notes – Any notes applied when the batch was created

NumFileAttachments – Number of Document links against this batch

NumBrokenLinks – Number of Document link broken links against this batch

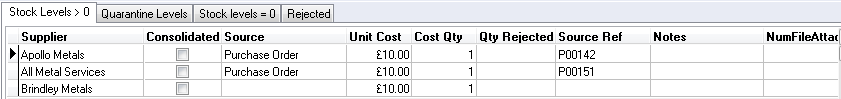

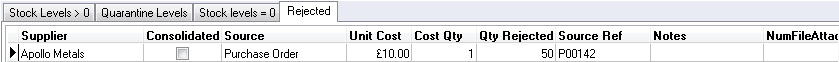

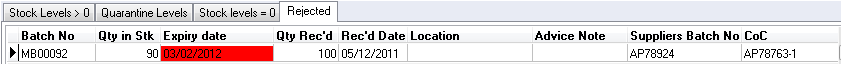

Rejected Materials – Displays if any of the materials of the current stock record have been rejected

Batch No – Internal batch number assigned

Qty in Stk – Quantity currently in stock against the batch

Expiry date – Displays an assigned expiry date, if this expiry date has been exceeded this will highlight the field in red

Qty Rec’d – The initial quantity received

Rec’d Date – Date the initial quantity was received

Location – The assigned location of the stock

Advice Note – Advice Note provided by the supplier

Suppliers Batch No – Suppliers own Batch

Supplier – Supplier of the materials

Consolidated – Used when consolidating materials with no traceability requirement

Source – The source of the stock entry

Unit Cost – Unit cost of the material

Cost Qty – Cost of the per quantity

Qty Rejected – Quantity of rejected materials against the batch

Source Ref – The reference of the source i.e. Purchase Order Number

Notes – Any notes applied when the batch was created

NumFileAttachments – Number of Document links against this batch

NumBrokenLinks – Number of Document link broken links against this batch

Data appears in this part of the screen by two methods.

Manual entry – e.g. Initial load or adjustments, perhaps adding the balance of material left over from material ordered specifically for a work order

Goods Inwards – when purchase orders for stock gets booked in

To work with data in the grid use the buttons at the bottom of the screen