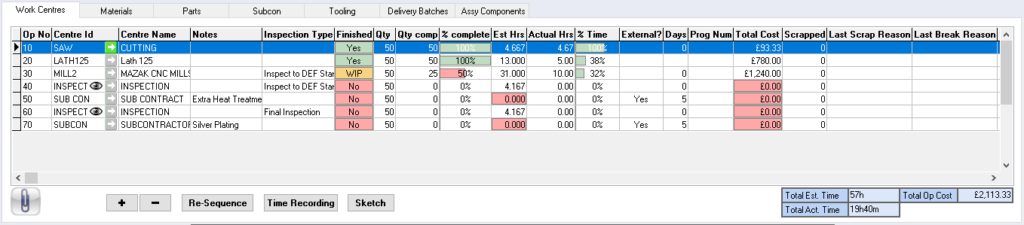

Work Centres Subtab

Work Centre subtab collates all operations required for this works order.

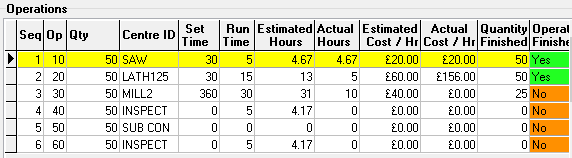

Op No – operation number

Centre ID – centre ID as assigned when creating work centres

Centre Name – centre ID Name

Notes – notes assigned to the operation

Inspection Type – Inspection types can be added to an operation in lieu of an inspection op. If SFDCe is in use these inspection types can be assigned to restrict the progress to another op requiring an inspector’s signature

Finished – indicates the status of operation Yes/No/WIP, colour will change accordingly, Red for not started, Yellow work in progress and green for finished. Use the CTRL key and click on this field to open a mini time recording window, enter the actual time, date and quantity finished for this operation

Qty – quantity required for the works order

Qty comp – quantity complete

% complete – quantity complete in percentage terms

Est Hrs – estimated hours for this operation

Actual Hrs – actual hours posted for this operation

% Time – percentage of time actuals vs estimates

Total Cost – estimated total cost for this operation

Cost_Per_Hour – cost per hour for this operation

External? – is this operation a subcon operation

Days – number of days this operation is due to be external (subcon)

Prog Num – program number of the operation

Scrapped – how many have been scrapped, used in conjunction with SFDC-e

Last Scrap Reason – reason for scrapping, used in conjunction with SFDC-e

Last Break Reason – reason for last break, used in conjunction with SFDC-e

Set Mins – setting time for operation

Run Mins – unit run time for operation

Insp. Level – inspection level as assigned within work centres

Uplift % – percentage uplift for this operation

Op No – when looking within this view relates to the operation number

![]() – add new record

– add new record

![]() – delete record

– delete record

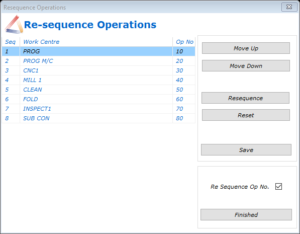

Re-sequence

Re-sequence button will re-sequence the operations as required. Select the operation to be moved, use the Move Up/Move Down buttons to reposition. Select Resequence to reset the sequence numbers, Save to save all changes, Finished to close window

Time Recording – see Time Recording

Sketch – a drawing can be added to the operation line, this must be in bitmap format.

Document link

Files can be attached to the group of operations.

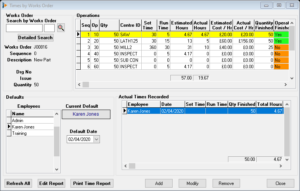

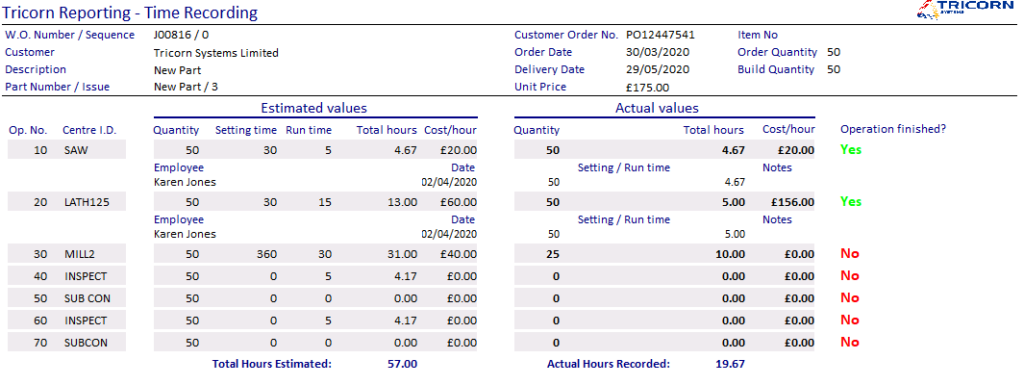

Time Recording

Time recording is used to record all actual times against each operation. Select the Time Recording button to open the Times by Works Order window (this can also be opened through the Menu Bar – Process – Works Orders – Time Recording)

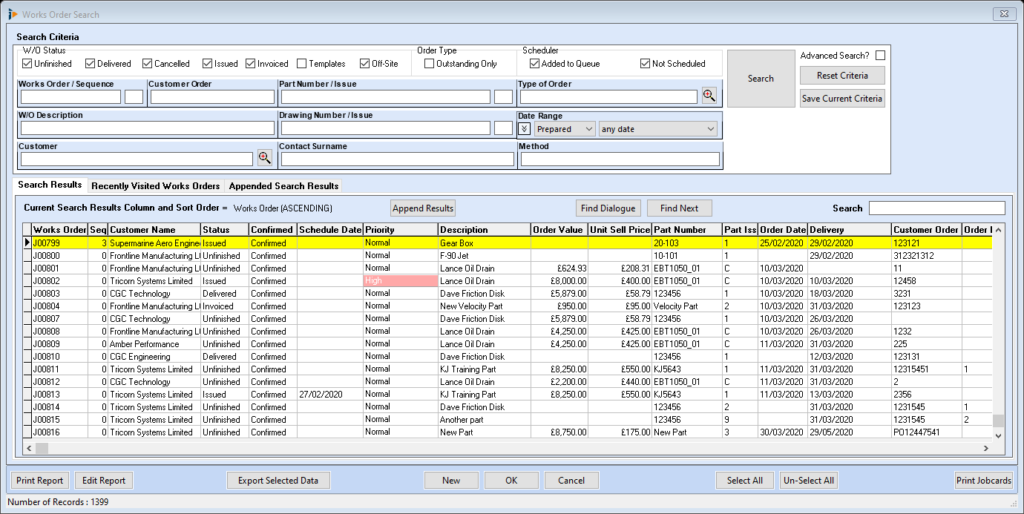

Works Order – Search by Works Order – use Detailed Search to open the works order search screen

Operations – table listing all operations for the works order

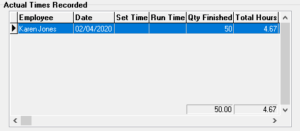

Actual Times Recorded – table listing all times posted against the operation

Defaults – Employees – list of all employees

Current Default – the current employee selected

Default Date – date all operations are to be posted against

Refresh All – refreshes the Times by Works Order window

Edit Report – contact Tricorn Systems for assistance

Print Time Report – prints a report indicating times posted against each employee on the selected works order

Add – add new record, opens the Enter Actual Employee Times window

Modify – use to modify an existing record

Remove – will remove the record from the Actual Times Recorded table

Close – close the window

Record Times against a Works Order

Highlight the employee to assign time against, a black triangle will indicate the selection.

Highlight the operation in the Operations table.

Select the Add button to open the Enter Actual Employee Time window, insert all required information. If the operation is finished ensure the box is ticked; to record any information relating to this operation notes can be included in the Notes field for future reference

Bar Code/SFDC-e – these times are viewable within this same program where corrections can be made if necessary

Times will be recorded in the Actual Times Recorded table, multiple entries against the same operation will be listed with accumulative time and quantity

Sketch

The sketch button enables a.bitmap drawing to be attached to the highlighted operation

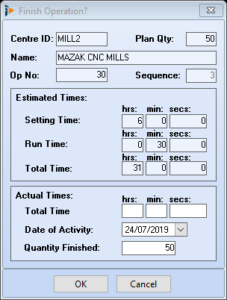

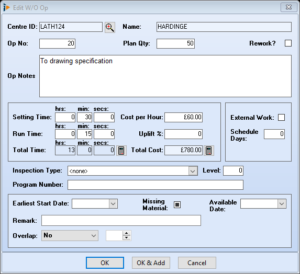

Works Order Op Window

Works Order op window will open when the + add button is selected

Centre ID/Name – centre ID and name as assigned when creating the work centre

![]() Centre ID looking glass button – used to change the operation

Centre ID looking glass button – used to change the operation

Op No – operation number

Sequence – sequence number of operation

Plan Qty – quantity to be manufactured

Op Notes – operation notes, it is possible to double click in this field to open a free type window where fonts can be changed, coloured etc.

Setting Time – setting time for operation, split into hours, minutes and seconds

Run Time – unit run time for operation, split into hours, minutes and seconds

Cost per Hour – cost per hour for operation

Uplift % – percentage uplift for this operation

Total Hours – total hours for this operation, indicated in hours, minutes and seconds. Calculator recalculates the total time

Total Cost – total cost for this operation. Calculator recalculates the total cost

External Work – is this operation a subcon operation? Tick if yes

Schedule Days – how many schedule days for this operation, can be populated from work centre

Inspection Level – inspection level as assigned within work centre

![]() Recalculate button

Recalculate button

Program Number – machine program number of operation

Settings for use in Scheduler only

These settings will only appear if scheduler has been activated.

Earliest Start Date – set the earliest date the operation can realistically start

Missing Materials – if materials are not available can indicate using tick box

Available Date – linked to missing materials, a date can be set for when the materials can be available

Remark – enter any detail relating to the missing material

Overlap – can set the overlap by Free, Percent and Delay, use the up and down arrows to enter value

OK – saves and closes window

OK & Add – saves and opens work centre picking list

Cancel – closes window no record saved