Works Order Tab

Works Order tab collates all production information in one easy to view screen. It can be split into sections making it easy to navigate, blue shaded and white areas.

Blue shaded area

Order Number – order number automatically populated from the number stack

![]() – assembly explode button

– assembly explode button

Prepared – date works order was created

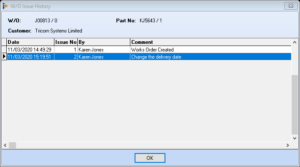

Issue – used to identify changes within the works order by up-issuing the order

Use the ![]() button to add new record, the new Issue W/O window will appear, enter relevant text

button to add new record, the new Issue W/O window will appear, enter relevant text

To view all records, use the ![]() button

button

Delivery – Delivery date

Status – Status of the works order

Type – Use to identify the type of work, this is a self-learning field any typed entry will be saved

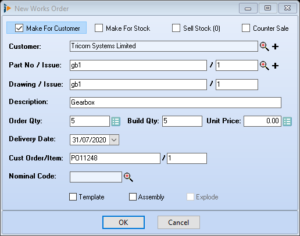

Customer – customer name retrieved from customer database

Location – customer address used for delivery purposes

Contact – contact for this customer; email correspondence will be sent to this contact if email address is present

Cust Order – customer order number

Item – used for further identification, can indicate the level of works order when a customer has sent multiple jobs

Item + – when entering works orders to cover multiple customer order lines, use the + to raise a new works order thus retaining the customer, order number and incrementing the item number

Acknowledgement Required – when clicked will generate a printed acknowledgement which can also be emailed. Settings for acknowledgements are setup in the customer record

![]()

![]()

Contract – this number is populated from the quotation enquiry number but can be used to record all jobs under the same contract number

White area

Part No/Issue – part number detail from part database

Drg No/Issue – drawing number detail applied to part record

Description – description is automatically populated from part database detail

Order Qty – quantity ordered by customer

![]() Part Selling price – setup against the part record

Part Selling price – setup against the part record

Build Qty – quantity planned to manufacture

Long Description – enter additional information relating to the manufactured part

Assy Level – indicates the level this part sits within the assembly

Top? – tick box to indicate this is the assembly top level

In Stock – indicates this part is in stock and the quantity

Quarantine – indicates this part is in quarantine and the quantity

Kits Ready – looks at the sourcing of parts and materials and will show how many of the required items could be built. This is based on the quantity of these items sourced from stock or received on a purchase order

Method – used to identify method processes, also used as a search function and defining multiple templates for one part

Location – can be used to indicate the location of this part whilst in production, in particular when using SFDCe